Corner guard protection is an effective and simple strategy for reducing maintenance costs. As time passes, whether it is residential or commercial walls, damages can occur that destroy the overall appearance of the place. One of the best things about corner guards is that it can be customized to match the décor of the place. They are considered the top protection products when it comes to walls.

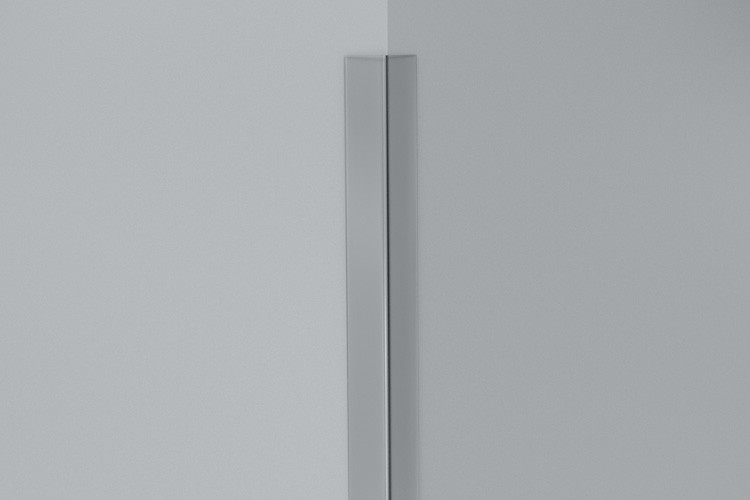

A corner guard sits flush above the edge of the wall where two surfaces meet. Typically, when fitted, corner guard protection forms a 90° angle, which is ideal for a good number of applications. Corner guards are also available in flexible material but are not recommended for commercial use.

The three main categories of corner guards include metal, flexible and rigid. Following are these three categories explained in detail:

1. Flexible Corner Protection

Flexible corner guard is both pliable and tough. They are mostly made from heavy-duty vinyl and are aesthetically appealing. Due to its makeup, the material provides protection and flexibility at the same time, which is a unique combination. This corner guard is best for tight areas or wall corners that are oddly shaped. They are available in various colors and designs and are preferred by most people for indoor application.

2. Rigid Corner Protection

Firm and strong, rigid corner guards are built to last. They are mostly used in environments where the wall has a soft surface. When it comes to fielding impacts, rigid corner guards are the first that take on the damage from wheeled carts, chairs and personnel. One of the best qualities of this corner guard is that its commercial-grade material displaces shock by effectively absorbing it upon impact. This protects the underlying wood or plaster and prevents damage to the actual wall. So, if the comer guard does get damage, you don’t have to worry about spending big bucks on maintenance because the corner guard will only need changing.

One corner guard material that falls under this category is polycarbonate. It has a see through surface, which makes it a popular application in residential areas because it does not disrupt the interior décor.

3. Metal Corner Protection

In some places, more protection is needed due to the high foot traffic. Places such as hospitals, commercial kitchens, transportation depots and garages require metal protection because they are met with more accidents. From stainless steel to aluminum alloy and 16-gage steel, all are great options for these places. These corner guards lower the damage from impacts and keep the professional façade of the building intact.

Metal corner guards prevent chips and cracks that occur due to beds being pushed into corners. As for steel corner guards, they are in compliance with the buildings’ regulations in areas of food prep. Lastly, stainless steel provides maximum protection and maintains the buildings’ design standards. Most metal corner guards are available in different finishes that go well with the design theme of industrial areas. One of the most popular corner guard protections is the aluminum checkered plate, which is great for plaster and brick wall corners.

So, there you go… three corner guard applications to choose from for any residential or commercial project. One feature that all these corner guards have in common is their strength. Therefore, no matter which material you chose, it will give lost lasting results.